SportMaster Sport Surfaces are advanced, 100% acrylic coating systems for surfacing of tennis courts and other sport court and recreational areas.

SportMaster is a proud member of the American Sports Builders Association (ASBA). Our systems are best utilized over a properly constructed surface. The ASBA maintains a complete set of detailed tennis court construction guidelines.

SportMaster Certification:

Mondo is specialised in the production of sports, commercial and industrial floorings on the highest standard. Known above all for its sports floorings, particularly athletics tracks and artificial grass fields, Mondo has been designated as Official Supplier of the Olympic Games on ten consecutive occasions, from Montreal 1976 to London 2012. About 150.000 athletes per year train and compete on Mondo floorings and equipments.

The company’s Sports division is able to supply not only surfaces for football, athletic tracks, volleyball, basket, aerobics, but also sports equipment, video screens, electronic scoreboards and seating for stadium & arenas and sport facilities. This is possible thanks to its large investments in technological research and human resources. The heart of the company’s operations and the driving force behind its international success in a wide variety of applications is the Mondo Research Center which, works in collaboration with prestigious research institutes specialized in a various fields, such as biomechanics, sports medicine and innovative materials. Its civil range includes rubber and vinyl floorings for means of transport, airports, hospitals, universities and schools, commercial centers and public buildings.

Mondo Certification:

Limonta Sport is a leading company in the production and distribution of synthetic grass for sport, thanks to its 30 years of experience, an efficient and dynamic distributive network, and to a long lasting relationship with the major sports Governing Bodies all over the world.

History

- 1979 – First production of the Limonta Sport Football Turf field

- 1994 – Establishment of Limonta Sport Iberica

- 1998 – First production of the Limonta Sport 3G soccer field

- 2002 – First installation of SoccerPro Top

- 2004 – First tests and installations with InfillPro Geo

- 2005 – Official establishment of Limonta Sport Italia

- 2007 – Installation of the first FIFA field Recomended 2 Stars with InfillPro Geo (Teramo, Italy) First PU production

- 2009 – Limonta Sport is confirmed as a FIFA Preferred Producer for Football Turf

Innovation

Limonta Sport has a fully-equipped, in-house laboratory to execute all R&Dand innovation projects. Where needed, the company undergoes project development with selected partners and leading universities. Continuous product and system testing assures quality as well as generating permanent improvements.

Total Quality Management

As an active participant in the sports world, Limonta Sport cooperates with many the international sports federations as both licensees and members as well as through many informal cooperation initiatives. The Limonta Sport Group is clearly focused on a close cooperation with its distribution partners, aiming at a substantial market-share that can sustain a desired level of investment in research and development.

Innovation is a key element in bringing the latest technology and a clear differentiation to our business partners.

As an ISO 9001 certified company, Limonta Sport carefully screens all initiatives based on sustainability. The development of greener backing, usage of environmentally-friendly yarn and the creation of InfillPro Geo, a 100% natural infill, are important initiatives showing Limonta Sport specific attention to the environment.

Limonto Certification:

Forbo Flooring Systems is a global market player in linoleum, vinyl, textile and flocked floor coverings as well as entrance flooring systems, where it has a market share of over 60%. Forbo Flooring Systems is part of the Swiss Forbo Group and owns 12 manufacturing plants and branches in 32 countries worldwide.

Forbo Flooring Systems has 12 production facilities situated in various countries.

Vision

As a global leader in flooring systems we create better environments and more rewarding opportunities for all our stakeholders.

Mission

Our way to serve and drive the market sets the pace and standard for world class flooring solutions.

Strategy

- Offer a broad product portfolio, leading in product performance and design

- Continuously improve products and processes

- Demonstrate commitment to the environment

- Develop knowledgeable, skilled and dedicated people

- Excel in customer service, delivering the highest level of customer satisfaction

Milestones of Forbo Group

- 2008: Acquisition of Bonar Floors, a major European flooring manufacturer in the contract flooring sector. With this, Flooring Systems strengthens its leading position as a systems provider of resilient flooring solutions in the commercial market. Forbo acquires the lightweight PVC conveyor belting business from Fenner Dunlop (Charlotte) Inc. North America as a further step to strengthen its Movement Systems division.

- 2007: New branding and growth strategy; three core divisions – flooring, adhesives and belting – renamed Flooring Systems, Bonding Systems and Movement Systems, operating under the Forbo brand with an integrated business strategy.

- 2004 – 2006: Strategic focus on three core divisions reaffirmed. Restructuring and measures to raise profitability. Acquisition of Chinese adhesives manufacturer specialized in hot-melt and water-based adhesives.

- 2000 – 2003: Adhesives gains world stature by acquiring Swift, operating worldwide from the USA, Europe and Asia. Belting business expands in Britain. Linoleum and Vinyl merged to create Forbo Flooring. Now three strategic businesses: Flooring, Adhesives and Belting.

- 2000 – 2001: New strategy focusing on four divisions: Linoleum, Vinyl, Belting and Adhesives. Divestment of industrial activities, including extruded profiles, decorative products and coated textiles. Carpet business spun off in management buyout. A series of minor acquisitions to strengthen Adhesives business.

- 1996 – 1998: Divestment of wall-coverings and laminates activities.

- 1994: Acquisition of Siegling, specializing in process and conveyor belt systems.

- 1975 – 1994: Forbo evolves into a worldwide group operating on five continents: acquisition of a flooring business in Britain; diversification into wall-coverings and high-pressure laminates.

- 1973 – 1974: Adhesives activities hived off from linoleum business to be developed independently. Continentale Linoleum Union is renamed Forbo to reflect the wider portfolio of activities.

- 1950 – 1973: Diversification into related products such as carpets and vinyl flooring.

- 1928: Three linoleum manufacturers – German, Swedish and Swiss – form the Continentale Linoleum Union.

Forbo Flooring Collections

- Linoleum

- Project Vinyl

- ESD & Cleanroom Flooring

- Flotex Flocked Flooring

- Textile

- Entrance Flooring System

- Acoustic Floors

Koochieplay Systems began as a dream. The dream [after all everything begins with a dream] we had, was not just making or selling playground and outdoor fitness systems like no one else did, nor was it to offer a product that everyone wanted, but to offer TOTAL SOLUTIONS which would include, SAFETY [our foremost concern], MEETING INTERNATIONAL STANDARDS [in terms of design, aesthetics, product life, quality, planning & execution], REDEFINING & ACHIEVING A SUCCESSFUL BALANCE between safety, reliability, quality and excellence.

Koochie is a Global brand spanning 4 continents and 8 countries, with its presence in France, Australia, India, Lebanon, U.A.E, Sri Lanka, Philippines & Morocco.

With 15 offices, and over 180 employees worldwide, we provide a wide spectrum of unique solutions and services to a clientele of premier organisations in the government [such as muncipalities and public parks] and private sectors [such as premium builders, schools, hotels, resorts, clubs, malls, fast food chains etc].

All through its rapid expansion, Koochie’s essential values stand firm and are reflected across all its installations carried out in various parts of the world. The difference KOOCHIE has brought about is not a consequence of any contrived effort but is a direct result of keeping faith in certain core values and not getting carried away with the flow.

Every component that goes into a Koochie system is manufactured in world class, state of the art O.E.M facilities located in Korea, Taiwan and China.

Koochie has its localized infrastructure in every major city in India [Bangalore, Chennai, Mumbai, Delhi, Hyderabad, Pune and Ahmedabad], whilst its overseas offices are in Paris, Sydney, Manila, Colombo, Dubai, Beirut and Casablanca.

Koochie’s design and support team is located in Chennai and is totally equipped to provide all our customers globally, with state of the art design and R&D support in terms of 3D, Auto-CAD layouts and base plan design.

End-to-end solutions capability – We manage turnkey projects, right from Consulting, Designing, Building and Installing our systems in various parts of the world. Our business is structured to provide a “One Stop Total Solutions” to all our clients. Our extensive experience in the playground industry, helps provide our customers, total solutions, right from choosing the right equipment, subsequent flooring, to finally building a playground that will make a project extremely unique.

Strong customer relationships – Koochie’s customer orientation and service culture lead to enduring bonds with clients. Our distinct value proposition and service culture, coupled with our track record of successful service and product delivery, are reflected in our long-standing customer relationships with dominant players in key infrastructure services and government sectors.

Strong service delivery chain – We have established an extensive services network in all key cities of Bangalore, Mumbai, Chennai, Pune, Hyderabad, Ahemedabad and Delhi in India, and our overseas offices in Paris, Sydney, Manila, Colombo, Dubai, Beirut and Casablanca which gives us an unmatched advantage in servicing customers with localized presence.

PRODUCT PROFILE

Koochie’s playground and outdoor fitness systems are a revolutionary concept that creates state of the art playground, outdoor fitness equipment & safety flooring tiles manufactured to meet all international standards in terms of design, aesthetics, product durability and most important child safety. Our playground and fitness systems primarily consist of two elements, steel components and plastic components.

All steel components are manufactured from the world’s best steel, which is first sand blasted, flow, coated, hot dip galvanized and finally powder coated to perfection. A Koochie system’s main pillar post is made of solid 114mm OD steel. Our paint technology is nothing short of what is used in the automobile industry [we use world class coatings from Akzo-NOBEL’s Interpon range]. Similarly koochie has pioneered the use of robotic welding in our metal components.

All plastic components are manufactured from virgin LLDPE that is imported from Samsung {Korea} and then Rotomoulded to ensure uniform wall thickness. All our plastic components [even our very large slides] are made out of single ROTO MOULDS, which ensure virtually seamless parts thus eliminating joints and ensuring a fantastic smooth heavy-duty plastic surface that is 100% child safe to use.

PRODUCT TECHNICAL SPECIFICATIONS

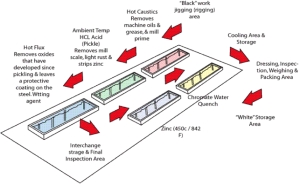

PILLARS / POSTS: All pipes / posts used in our multi play systems are made from 114mm galvanized steel. These posts are fabricated with 114mm (0.37ft) O.D. galvanized steel tubes, Steel quality confirming to BS1387-1985. All tubing used to manufacture components are electrical resistance, ROBOTIC welded, hot rolled and high strength steel tubing. The interior coating consists of an in line hot dipped uniform zinc galvanizing, after which this is sand blasted, later flow coated and then finally powder coated [with AkzoNobel Interpon coatings] to perfection. Due to this stringent process and technology our metal components are virtually indestructible and do not rust or corrode easily. The THICKER structures we use ultimately result in a stronger and a more stable play structure.

POWDER COATING FINISH: Electro statically applied with ourcustom formula of TGIC polyester powder and AkzoNOBEL’s world famous INTERPON powder coatings. All components are free of sharp edges and excess weld splatter and are cleaned in a six stage bath system with an iron phosphate wash, as a rust inhibitor and a sealer to prevent flash rusting before coating. The coating has a super tough finish with maximum exterior durability and will have superior adhesion characteristics. Typical characteristics are 3.0 mil thickness.

The process methodology used: Hot rolled steel —-> cleaned edges and weld spatter —–> iron phosphate wash —-> paint rust inhibitor —-> drying —-> powder coated with TGIC polyester.

PLASTIC COMPONENTS: All plastic components are made from ‘VIRGIN LLDPE’ granules that we import from SAMSUNG [KOREA] which is then roto moulded to perfection to create UNIQUE, PATENTED ANIMATED roofs and panels that are most unique in design, style and colours. WE DO NOT USE ANY FIBRE GLASS – ONLY THE WORLDS BEST PLASTIC WHICH IS U.V STABILIZED and does not crack or fade. Our unique animated roofs and panels make KOOCHIE systems very attractive as compared to the other boring plain square or round roofs .

ROOFS: All our roofs & shades are made from 100% virgin LLDPE imported from SAMSUNG KOREA. All Koochie roofs are patented and are ROTOMOULDED to provide seamless ANIMATED, 4 dimensioned, attractively designed and coloured ROOFS with uniform wall thickness.

PANELS: All our panels are made from 100% virgin LLDPE imported from SAMSUNG KOREA. All Koochie panels are ROTOMOULDED to provide seamless ANIMATED, 4D attractively designed and coloured panels with uniform wall thickness.

POLY EHTYLENE COMPONENTS: All our P.E components are made from ULTRA HIGH MOLECULAR WEIGHT MATERIAL HANDRAILS: All our handrails are manufactured from 32mm (1.26’’) O.D. galvanized tubes. All tubing used to manufacture components are electrical resistance welded, hot rolled, high strength steel tubing. The interior coating will consist of an in line hot dipped uniform zinc galvanizing.

SWING SEATS: Our Floppy swing seats are made from high grade plastic while our Firm swing seats are made from High Grade UV Stabilized Plastic.

LADDERS: Our ladder assemblies are made from 2mm (0.079’’) thick punched steel. The steps and stringers are all welded assemblies with an electro-statically applied custom formula of TGIC polyester powder. The ladder handrails are fabricated to 1.26’’ O.D. galvanized pipe with a powder coated finish.

FASTNERS: All KOOCHIE products use a unique, minimal maintenance fastening system called the TRUE SAFE system. This includes a solid, factory compatible designed construction, and corrosion resistant galvanized steel fasteners. This system boasts a clean, European look and makes the whole play structure an extremely solid and safe unit. The traditional welded system is bulky, unsightly and is known to be problematic over a period of time .

FABRICATION: All steel components are manufactured in our factory using state of the art cutting and brazing technology which is then well finished to ensure smooth lines and perfect geometry. All parts are then sand blasted, hot dipped galvanized and flow coated which is then powder coated using the world’s best powder coating technology. All welding is done by state of the art ROBOTIC WELDING MACHINES.

KOOCHIE DECKS & STAIRS: Our rectangular & square decks & stairs are fabricated from 2mm (0.079’’) thick punched steel with a powder coated finish. The deck is a one–piece assembly with electro statically applied custom formula of TGIC polyester powder. Our decks are also available in plastisol [rubberized] coating which helps reduce heat & noise besides making it a safer option for children .

WHY KOOCHIE? IT’S UNIQUE – Our unique, patented, animated roofs, panels, slides etc are designed to make any child squeal out in delight. At Koochie, we have revolutionized the concept of playground equipments. Remember, these products are intended for use by little children, we at koochie have taken years of research to understand what really appeals to them. Our animated sun and crab roofs have been designed with this particular intention in mind.

- ADDS VALUE – Koochie’s patented animated designs with its bright lively colours add value to any project upon which a Koochie system is installed. A Koochie system is guaranteed to enhance your projects aesthetics by bringing in a lively, beautiful surrounding environment.

- LONG LASTING – Every Koochie product is built to withstand the test of time and more important the test of children. Koochie systems are solid, stable and rugged. WE MAKE OUR SYSTEMS SOLID.

- LIFE SPAN – Koochie systems are built to last for at least 15-20 years.

- ALL SEASON USAGE – Koochie systems have been installed in nearly every climatic condition, be it humid summers or freezing winters.

- MAINTENANCE FREE – Koochie systems are built without the need for any major regular maintenance.

EVERY KOOCHIE SYSTEM is made by a specialist DESIGN / R&D & MANUFACTURE Team to ensure all INTERNATIONAL STANDARDS are met in terms of design, aesthetics, product life and most importantly CHILD SAFETY.

Sports Construction with Artificial Turf

At GreenFields® we are committed to producing the most innovative and technologically advanced synthetic turf systems in the world. We accomplish this through our years of experience in manufacturing, construction and installation, our long-standing commitment to research and development and our unwavering commitment to complete customer satisfaction. Our complete in-house laboratory and our strong exclusive partnerships allow us to design and build synthetic turf systems for a variety of sports that are unequalled within the industry.

Our goal is to be recognized as the world’s premier brand in the world of all-in-one sports turf systems. We strive to provide the absolute best experience for everyone involved in the game from the players, coaches and referees to the people in the stands cheering them on. We are achieving this goal through our commitment to quality in all facets of athletic field construction, through the integration of quality, environmentally responsible components and innovative design, and through a commitment to service that is unsurpassed anywhere in the industry.

Vision

We truly believe that sport unites and re-unites people and can be used as a tool for positive social change. The fundamental objective of GreenFields is to enable everyone all over the world to play sports on good, sustainable, environmentally friendly and safe surfaces.

GreenFields aims to be the best in developing, producing, installing and maintaining these surfaces, while respecting the environment and committing to social responsibility. We understand the impact of sports and as a key-player within the industry and the world of sports, GreenFields sees it as a duty and faces the challenge to balance social responsibility with our development as a company.

Mission

GreenFields wants to be recognized as the no. 1 brand that supplies all-in-one sports turf systems for the good of the players and the game.

GreenFields wants to grow through strategic expansion on a worldwide level and increase its market share by offering new synthetic turf systems. In order to reach this GreenFields will focus on quality of products, innovation and support while respecting the environment and committing to social responsibility.

Greenfields Certification:

Shanghai Huiyu Fine Chemicals Co., Ltd set up in 1993 that is filiale by Taiwan Headway Chemicals Group. Our company production and sales including: PU paint, synthetic surface paint, court paint, waterproof paint, floor paint, premium wooden ware paint and PU color cream, and undertake the construction of playground tack, court and artificial turf.

We have over 10 years experience in the industries of sports, coating and paint and the brand “Lesutan” has become a well-known one in sports field throughout the eastern area of China.

Our company has a group of experienced professional production technicians who continuously develop new products to ensure that our

company is in the leading position in this field. In addition, we have professional construction process and strict and normative check

methods which enable our products to be perfect from production through design to construction and to meet your requirements.

Our company has been awarded the certificate of 150-9001 :2000 quality assurance system. The PU synthetic surface won the “Certificate of Sports Field Professional Grade Qualification”. Now we have passed the check of sports field material and obtained the certificates by IAAF that is full polyurethane (LESUTAN P) synthetic surface, sandwich system(LESUTAN S)synthetic surface and spray coating(LESUTAN V) synthetic surface.

Currently, our company holds the idea “good quality, advanced technology, professional service” and becomes a leader in the industry competition. However, all staff of our company will put into practice to repay various circles for their kindness with a service spirit of “persistent advance, steady efforts, greater perfection”.

Product profile

The track is divided into the types of full polyurethane, sandwich system, spray coat system , while the ball field is divided into the types of pure PU ball field, compound, space, EPDM and acrylic acid, The multiple types are ready to offer you with the one-stop service from design, planning to construction.

Lesutan Certification:

STOCKMEIER Urethanes develops, manufactures and sells polyurethane systems

Our offer includes:

• Products for the construction of sports flooring installations for outdoor (running tracks, playgrounds, tennis courts), sports halls and children’s playground and artificial turf fields.

• Casting resins and compounds for the electronics industry, as well as hard and soft casting compounds for the manufacture of technical items and molded parts

• Adhesives and sealants for a variety of applications in the industrial sector ( automotive industry, industrial batteries, air and oil filtration, panel manufacturing, recycling and consumer products)

Three full-size manufacturing plants around the world are our activities both locally and globally oriented. Comprehensive and customer-oriented consulting is a part of the self-conception of STOCKMEIER Urethanes. Ensuring a continuous prime product quality is the key-element of our daily work.

Stockmeier Certification: